Southeastern Automation, Inc.

PO Box 22820

Knoxville, TN 37933-0820

Phone: (865) 675-3080

Fax: (865) 675-3060

www.southeastern-automation.com

| USA SALES ONLY |

|

|

Southeastern Automation, Inc. |

| |

PROCESS ANALYZER ACCESSORIES

|

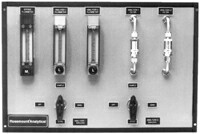

Process Analyzer Flow Control Module (6100) |

|

Sample Gas Conditioning System - Heated (6300) Many gas analyzers are operated at elevated temperatures to eliminate condensation of the sample stream. The Model 6300 Heated Sample Gas Conditioning System is used for wet measurements, wherein moisture or other condensable compounds are maintained in gas phase. |

|

Sample Gas Conditioning System - Multi-Purpose (6500) |

|

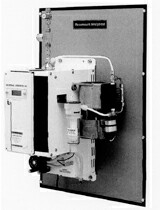

Sample Pressure Regulating System (6200) Many analytical methods are very sensitive to fluctation in sample pressure. With the pressure regulating system, we are able to eliminate the inaccuracy in the analyzer reading caused by fluctuating sample pressure. The high-precision adjustable pressure regulator and gauge allows regulation of the sample input pressure to the analyzer(s). The pressure regulating system can be mounted at the sample take-off point. By reducing sample pressure at the take-off point, the hazards associated with high pressure sample line are eliminated. The lower sample pressure reduces the sample lag time. A 60-micron guard filter prevents any damage to the pressure regulator and the analyzer(s). A relief valve is included to eliminate any accidents due to over pressurization and a sample shut-off valve is available to isolate the analyzer system for any preventive maintenance. The pressure regulating system can be used as a stand-alone system or it can also be used in conjunction with other Rosemount Analytical sample system modules. |