USA SALES ONLY

Southeastern Automation, Inc.

PO Box 22820

Knoxville, TN 37933-0820

Phone: (865) 675-3080

Fax: (865) 675-3060

www.southeastern-automation.com

| USA SALES ONLY |

|

|

Southeastern Automation, Inc. |

|

|

|

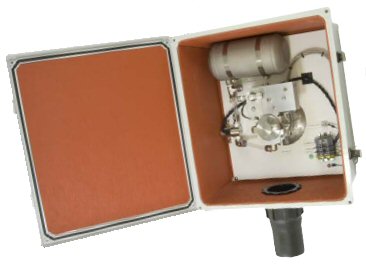

Baldwin's Direct Extractive Filter Probes feature an advanced design to extract sample gas and remove particulate while preventing condensation prior to the gas sample entering the heated sample line. New Machine-Lathed Sure-Lock™ Filter Assembly Baldwin's new Sure-Lock filter assembly is precision machined and features a unique design to help ensure proper insertion into the assembly and to reduce the possibility of leaks. The filter head is inserted into a notch in the assembly to ensure proper alignment before locking it in place. The o-rings are tightened under compression, rather than being located on the sides of the filter head, to reduce the risk of leakage.

|

|

Hazardous Area Applications Class 1 Division 1 & Class 1 Division 2 Baldwin's Direct Extractive Filter Probes feature an advanced design to extract sample gas and remove particulate while preventing condensation prior to the gas sample entering the heated sample line. New Machine-Lathed Sure-Lock™ Filter Assembly Baldwin's new Sure-Lock filter assembly is precision machined and features a unique design to help ensure proper insertion into the assembly and to reduce the possibility of leaks. The filter head is inserted into a notch in the assembly to ensure proper alignment before locking it in place. The o-rings are tightened under compression, rather than being located on the sides of the filter head, to reduce the risk of leakage.

|

|

Principle of Operation A precision, low flow, heated dilution eductor assembly driven by instrument quality air extracts sample gas from the process. The sample passes through a stinger and filter probe to remove particulate. The filter element is selected for its inertness to the sample gas; a ceramic element is standard. A conditioned source of instrument air connects to the dilution eductor. The flow through the critical orifice in the eductor creates the vacuum that pulls the sample gas through the dilution probe system. This air mixes with the sample, diluting the gas to a lower concentration and dew point. The dilution air and sample gas flow rate may be set by selecting a different orifice size. This orifice is made from precisely machined Monel. The design of the orifice restricts the gas flow to achieve sonic levels or the speed of sound, eliminating the effects of pressure fluctuations downstream. To maintain a constant dilution ratio, the precision dilution eductor draws the sample in at a slow rate of 25-700 cc/min. An optional fast loop eductor is available to reduce lag time between the probe tip and filter body, ensuring adequate sample supply. |