USA SALES ONLY

Southeastern Automation, Inc.

PO Box 22820

Knoxville, TN 37933-0820

Phone: (865) 675-3080

Fax: (865) 675-3060

www.southeastern-automation.com

| USA SALES ONLY |

|

|

Southeastern Automation, Inc. |

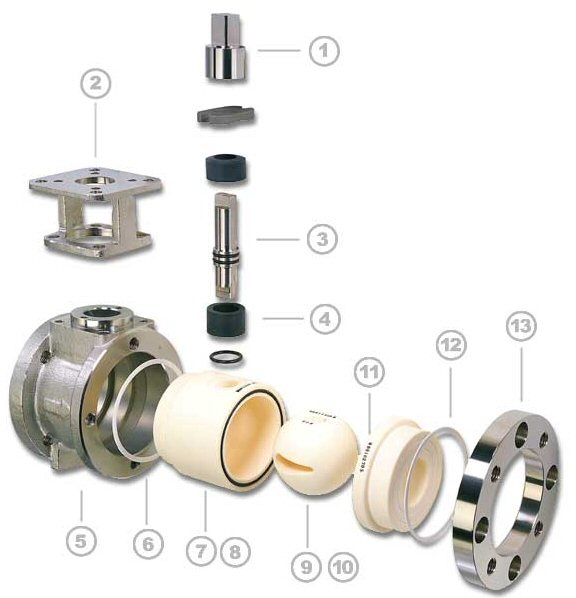

The Cosmix Ball Valve |

| Designed to Endure. The Cosmix ball valve was specifically engineered to withstand abrasion, corrosion or a combination of both. The standard ceramic material used in all Cosmix ball valves is 99.5% pure alumina ceramic, which is 8 times harder than stainless steel and 2½ times harder than Stellite®. Since the materials utilized in the Cosmix ball valve are so hard, this unique characteristic enables the valve to perform extremely well under the most erosive applications - including constant cavitation, high velocities, high differential pressures and high percent solids. |

|

|

Stainless Steel Coupling meets most square-drive actuator dimensions. Supplied coupling is typically the only component that may require modification for non-standard automation. |

|

|

Stainless Steel Mounting Pad provided with every valve meets the dimensional standards of ISO 5211 – which is the basis for a sturdy, clean, direct-fit onto most rotary actuator brands and models. The mounting pad may be removed to permit special automation packages, thus making the Cosmix valve very automation-friendly.

|

|

|

Hastelloy-C® Stem offers excellent corrosion-resistant properties and ample hardness to drive the ball indefinitely. Standard stem may be replaced with virtually any material to maximize process compatibility and longevity.

|

|

|

Carbon-Filled Teflon® is stiffer, has a higher temperature limit and does not cold-flow. O-Rings are kept energized without the need for periodic packing re-adjustment. |

|

|

Stainless Steel Housing allows the valve to be exposed to extremely harsh environments without external corrosive degradation. It securely encloses the ceramic components and protects them from any possible damage. Pipe stresses are not transferred to the ceramics but are absorbed by the housing – as all flange bolts are bolted directly onto the housing itself. |

|

|

PTFE Gaskets cushion the ceramic against the stainless steel and offer extra sealing protection should any of the ceramic components fail. |

|

|

Solid Ceramic Body fully encapsulates the ball and acts as the pressure containing vessel when assembled with the socket. This ensures that aggressive fluids do not come in contact with any of the external stainless steel components. |

|

|

Thick, Solid Ceramics. Proof of a sound, highly-engineered valve design. By utilizing solid, heavy-wall ceramic components, the valve is able to survive in continuous service far longer than coated or lined valves. This adds to the durability of the valve and is less susceptible to damage from abuse or rough handling.

|

|

|

Solid Ceramic Ball resists corrosion and abrasion and is offered in a wide variety of equal-percent and round ported styles. Floating-ball design requires very little actuation torque and minimizes the possibility of fracture due to over-torquing. Having a minimal amount of “dead-torque” allows the ability to handle high differentials, as well as having abundant strength to shave-off any surface accumulation. |

|

|

Equal Percent or Round-Port. Each line size offers up to five different trims; four equal-percent and one round-port. This variety of trims enables Fujikin to specify the perfect trim for precise control and minimized downstream seat wear.

|

|

|

Serialization enables us to follow every valve’s history – from manufacture to repair – information that allows constant product improvement and development. All ceramic components – as well as valve assembles – are assigned a unique serial number, which provides our end users with an increased level of technical support and order history tracking.

|

|

|

Solid Ceramic Socket resists abrasion and is not marred by trapped solids. Symmetrical in design, it may be rotated during scheduled maintenance to extend useable life up to twelve times. Grooved external sealing surface guarantees leak-free installations with low bolt torque. |

|

|

Stainless Steel Flange is held in place with flush hex socket bolts. This allows quick access to all internal components without the need for special tools, complicated alignment and assembly procedures, or time-consuming factory returns. In fact, valve repair is so simple and quick, we recommend it be done on-site. |